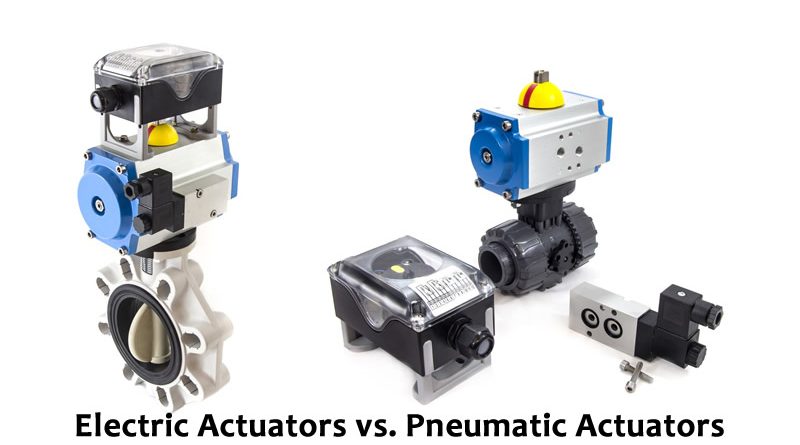

Electric Actuators vs. Pneumatic Actuators

Electric Actuators vs. Pneumatic Actuators

The debate between electric and pneumatic actuators has been going on for decades. On the surface, electric actuators are known for their higher levels of precision. But, some pneumatic actuators can still have precise motion as well. So, it can be challenging to find the best one for your needs.

Let’s look at the differences, advantages, and disadvantages of electric and pneumatic actuators.

What’s an Electric Actuator?

Electric actuators offer precise control and position, adapting machines to flexible processes and low operating costs. These devices are made of a ball, acme, or roller screw connected via a coupler to an electric motor. As the screw turns, it moves a piston, then the rod or carriage moves the load.

Electric actuators are available rod-style, or rodless, with or without motors and drives. Motors can be mounted axially behind the actuator body or parallel to the actuator in four positions.

Some advantages of electric actuators:

- Fast signal transmission speed

- Long transmission distance

- Centralized control

- High sensitivity and precision

- Simple installation

- Easy to cooperate with electric adjustment instruments

- Suitable for places with low explosion-proof requirements

Of all, one of the most significant advantages of electric actuators is their precise control and positioning. Since you’re able to preprogram stop positions, you can be extremely precise on the location. Plus, they’re generally faster and less noisy than their pneumatic counterparts.

What are Pneumatic Actuators?

A pneumatic actuator converts energy, usually from compressed air, into a mechanical motion. You can also find them as pneumatic cylinders, air cylinders, and air actuators. Pneumatic actuators have pistons, cylinders, valves, or ports that convert energy into linear or rotary mechanical motions.

This actuator is excellent for fitting to angle seat control valves and wide applications in various industries including, air compressors, aviation, and combustible automobile engines.

Some advantages of pneumatic actuators include:

- It doesn’t require electricity

- Can store compressed air without the risk of fire

- Extremely durable

- Less maintenance required

- Quick action and response time

Well-known for their clean operation and lack of ignition source, pneumatic actuators are very reliable. In addition, they have a low per-unit cost, which makes them very appealing to buyers. And, one of their most significant advantages is that they can produce some of the highest closing forces of all actuator types, with speeds and forces that can be fine-tuned to meet your needs.

Choosing the Right One

When deciding between an electric actuator and a pneumatic actuator, there are different things to consider. The most important factors are performance and cost, of course. After all, they both offer unique features and benefits that lend themselves to specific applications.

In the end, understanding how each system works and the type of application you need them for is crucial for determining the best type of actuator.

—

Geraldine Orentas is a writer from Happy Writers, Co. in partnership with Viking Fence automatic gate installation service.