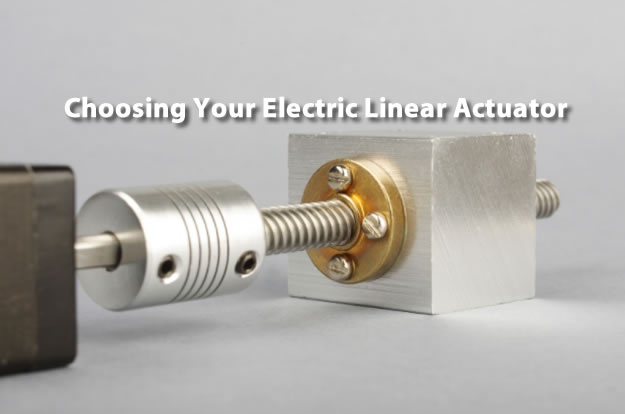

Choosing Your Electric Linear Actuator

A linear actuator, which is a device that converts an AC or DC electric motor’s rotational movement into linear movement, can be useful for projects from those that need micro-actuators, such as kitchen shelving that automatically extends outward toward the user, to large projects, such as installing secure, more maintenance free garage door openers. But the type of linear actuator you will need depends on a number of factors concerning the type of project involved.

Types of Linear Actuators

The most common formats for linear actuators involve the positioning of the motor.

- A parallel actuator places the motor next to and in line with the cylinder where the arm will extend.

- An L-drive or right-angle actuator, as its name suggests, places the motor at one end in right angle to the extension cylinder.

- Inline actuators incorporate the motor as an extension of the cylinder so that the unit is one long piece.

- A slide actuator foregoes an extension tube, utilizing instead a slide that moves along the length of the frame.

- Lifting columns are specifically designed to lift heavy loads and to resist bending or warping.

It is also important to note that other dynamics of the linear actuator come into play as you ascertain your needs. Motors for linear actuators are most often screw drives, but there are belt drive units available that may be more appropriate for projects where higher speeds or travel distances are required or where greater positioning accuracy is needed. If you need not only pushing force but also reciprocal pulling force, you will want to consider a dual motor set up.

What to Consider as You Choose

As you decide on the type of linear actuator you will use, you will need to consider whether the unit will be used inside or outside and what types of contaminants it might be exposed to. There are other basic determinations you should make before you choose:

- What are your space requirements? Tight spaces often require an inline system unless the space has less depth, in which case a parallel unit may be more applicable.

- Does the unit need to be silent? Worm gear driven units operate with less noise and are used in right angle actuators. They are, however, less efficient.

- What force will you need? In determining the required load on an actuator, you will want to determine whether the unit will push, pull, or both and also whether the load will be distributed vertically or horizontally.

- What are your distance and speed requirements? The distance or stroke length of a unit is the length the arm will extend in one direction. Longer lengths may require a belt driven unit. Speed, which is measured in distance per second, will be listed on the actuators spec sheet. Typically, the more force required the slower the unit.

- What is the “duty cycle” of the unit? The duty cycle is the ratio of time the unit will be in operation versus the time it will not. This may determine the materials from which the unit is constructed and the design of the internal components in order to maximize the lifetime of the unit and to limit the maintenance necessary.

—

Ivan Young is a writer from Happy Writer’s Co. in partnership with Viking Fence, an access control gate service.